Anaheim, Ca. based RC Industries was founded on the idea that a manufacturing company should provide more than just machined goods to customers. They provide full-circle product development services from concept design, creating prototype parts, to assembly, and delivery of high-quality manufactured products. “We are honored to contribute our unique full-circle services in many divisions within the manufacturing industry,” tells Rob Champlin, founder and president of RC Industries. “Our specialty is hard to machine, tight tolerance, high complexity parts for aerospace, automation, automotive, avionics, electronics, and medical devices. We have 20,000sq.ft. filled with 25+ 3, 4, and 5 axis CNC machining centers. And we are IS09001 and AS9100 certified.”

Rob Champlin got his start in the industry like many others, his mom found him a job. Rob was welding trailer hitches in Corona, Ca and looking for more part time work to fill his schedule. “My mom was employed by a forging company at that time,” tells Rob. “She asked one of the machine shops they did business with if there were any part time openings. The answer was no, but full time, 50 hours a week was on offer.” Being closer to home offset a slight pay cut, and Rob unknowingly began a career in manufacturing. “In high school I needed another elective and took auto shop over typing,” laughs Rob. “I didn’t think I would need that skill any more than I thought I needed sophomore geometry. Now here I am with essentially the same job since 1986 and I type everything and live a lot of my life within a Cartesian Coordinate System.”

RC Industries added the palletized 5 axis Doosan DFV500 back in December 2019 and it quickly has become a favorite. Rob looked at the price of vises when he got the Doosan and decided he was going to make his own palleting and fixtures. He settled on a design that gave him the most access. The Doosan is armed with an 8 pallet system.

He was a quick learner and within the first two years all the hard and critical jobs were going to Rob. Sadly, four years after Rob started his new career the company’s owner passed away. Rob ran the business for the widow for another four years before buying it off her and rebranding to RC Industries. “I was using the RC Industries name for all my side projects,” tells Rob. “It just made sense to continue on with it. That was 1994. We were mostly machining aluminum forgings back then. We still do, but we’ve grown a lot as a company and with our capabilities.” As the need for higher precision and automated manufacturing presented itself, Rob upgraded his equipment from conventional machines to 3-axis machining, then to 4-axis, and now 5-axis. “With each improvement, we’ve positioned ourselves higher and higher up the food chain as a leading provider of precision machined parts, tooling, forgings, castings, and hog-outs,” touts Rob.

For Rob and RC Industries 5-axis is everything. Admittedly If he were to start over, he would do it with a 5 axis Haas and a small dovetailing/second op machine. “Right off the bat you save money on tooling and fixturing with a setup like that,” explains Rob. “I put a dovetail on most parts and get 90% of the part done. Sometimes the part is 98% done and I just need to clean up a small ridge. We have half a dozen of the Haas 5 axis vertical machines and just love them. My big mill is a Haas VF7 84”x32” with a 4th axis trunnion. We have a bunch of VF4’s, and VF3’s, and 3 mini mills. The Haas machines are great. You get more than what you pay for out of them. They are easy to program and understand. Most people who come in looking for a job have experience running a Haas. They are by no means perfect, but if you look around this shop you will see I am a fan. We run the hell out of our Haas machining centers, but when it comes to 24/7 production my Okuma MB-400H and Doosan DVF 500 are called into action.”

For Rob and RC Industries 5-axis is everything. Admittedly If he were to start over, he would do it with a 5 axis Haas and a small dovetailing/second op machine. “Right off the bat you save money on tooling and fixturing with a setup like that,” explains Rob. “I put a dovetail on most parts and get 90% of the part done. Sometimes the part is 98% done and I just need to clean up a small ridge. We have half a dozen of the Haas 5 axis vertical machines and just love them. My big mill is a Haas VF7 84”x32” with a 4th axis trunnion. We have a bunch of VF4’s, and VF3’s, and 3 mini mills. The Haas machines are great. You get more than what you pay for out of them. They are easy to program and understand. Most people who come in looking for a job have experience running a Haas. They are by no means perfect, but if you look around this shop you will see I am a fan. We run the hell out of our Haas machining centers, but when it comes to 24/7 production my Okuma MB-400H and Doosan DVF 500 are called into action.”

The Okuma MB-400H is a beast of a production machine. With a 12 pallet Fastems system and 218 tools, it does some of its best work while everyone is fast asleep.

RC Industries added the Okuma MB-400 at the end of 2016. With a 12 pallet Fastems system, the Okuma is designed for lights out production running. “Our Okuma has 218 tools, and we regularly have 20 part numbers set up and ready to go when the customer needs them,” explains Rob. “It knows everything and will go from job to job-to-job 24/7. For example, the throttle housing I showed you earlier takes seven hours to machine. The rudder pedals are three hours for both, and the throttle levers take about two hours. Adds up to 12 hours of spindle time overnight. Come back the next morning and those parts are ready to go. Making money while we sleep. With 12 pallets we have the versatility needed to keep regularly scheduled jobs setup on deck and still have room to mount and machine whatever we need that isn’t in the normal rotation. It has a ton of HP, a fast spindle, and really is a great machine that we trust to run and run. It opened our eyes to the possibilities of palletized lights out manufacturing.”

RC Industries newest machining center is a 5 axis Doosan DVF 500 with 8 pallets. It was installed by Ellison Technologies and even during a global pandemic has quickly become a shop favorite. “Like on the Okuma, we tend to machine shorter runs during the day when employees are around to reload pallets,” tells Rob. “By the time the afternoon is here we are all set for overnight lights out manufacturing. The Doosan DVF 500 is a fast and accurate machine. We got it just before Covid in December 2019, and unfortunately with airline sales grinding to a halt I haven’t been able to utilize it at full capacity. Looking at sales orders, we are beginning to ramp production back up, and I expect it to be near capacity by the beginning of the year. I chose the Doosan DVF 500 for price, pallet system, number of tools, and the physical footprint.” RC Industries are overloaded with machines in their primary manufacturing building and have already began arranging machining centers in the JAMAR building next door. “The DVF 500 gives me advanced 5 axis capabilities, tool detection, a generous work envelope, has eight pallets, and takes up very little floor space,” continues Rob. “Blake Adham at Ellison Technologies is a super good guy, and we get fantastic service from Ellison. So far it has delivered everything that was promised. I had a couple of specific commercial airline parts in mind when deciding on the Doosan. They fit the capabilities perfectly. But honestly the machine is more versatile than I imagined. Programming and the controls are straight forward, my guys and I were able to adapt quickly to it. Right now, if we get a new part in that is more than 10 pieces our first thought is put it on the Doosan. We have four or five monthly jobs set up and ready to go on it at all times, and still have room to spare.”

RC Industries newest machining center is a 5 axis Doosan DVF 500 with 8 pallets. It was installed by Ellison Technologies and even during a global pandemic has quickly become a shop favorite. “Like on the Okuma, we tend to machine shorter runs during the day when employees are around to reload pallets,” tells Rob. “By the time the afternoon is here we are all set for overnight lights out manufacturing. The Doosan DVF 500 is a fast and accurate machine. We got it just before Covid in December 2019, and unfortunately with airline sales grinding to a halt I haven’t been able to utilize it at full capacity. Looking at sales orders, we are beginning to ramp production back up, and I expect it to be near capacity by the beginning of the year. I chose the Doosan DVF 500 for price, pallet system, number of tools, and the physical footprint.” RC Industries are overloaded with machines in their primary manufacturing building and have already began arranging machining centers in the JAMAR building next door. “The DVF 500 gives me advanced 5 axis capabilities, tool detection, a generous work envelope, has eight pallets, and takes up very little floor space,” continues Rob. “Blake Adham at Ellison Technologies is a super good guy, and we get fantastic service from Ellison. So far it has delivered everything that was promised. I had a couple of specific commercial airline parts in mind when deciding on the Doosan. They fit the capabilities perfectly. But honestly the machine is more versatile than I imagined. Programming and the controls are straight forward, my guys and I were able to adapt quickly to it. Right now, if we get a new part in that is more than 10 pieces our first thought is put it on the Doosan. We have four or five monthly jobs set up and ready to go on it at all times, and still have room to spare.”

As an ISO9001 and AS9100 certified company quality is king at RC Industries.

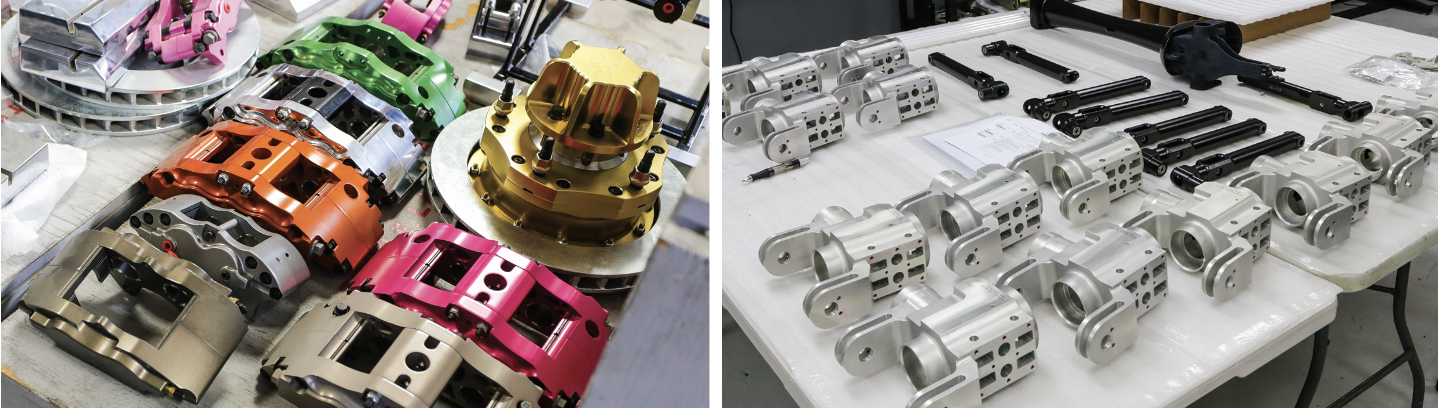

The last year and a half have been trying to say the least, but RC Industries were as prepared as possible. You can’t be in this game for three decades without being able to adapt to an always changing narrative. “We’ve been using the down swing in the commercial airline business to focus more on other industries,” adds Rob. “Our satellite customers are going gangbusters right now, and we are seeing more automotive and medical jobs come our way.” Everyone used the pandemic to pick up new hobbies. Side-by-sides and sand car sales are through the roof. That’s great for Rob’s other company JAMAR which produces high end aftermarket performance mods for off-road toys. Rob’s JAMAR products are keeping a lot of RC Industries’ machines busy and that will only increase as they head into prime sand season. “Overall, I think we are pulling up out of all this mess,” concludes Rob. “We are pulling up, but I still fear a tail strike, so we are spending wisely and running lean. I didn’t have to lay anyone off, we are cutting chips every day, producing quality parts, making deliveries and servicing the customers. Same as we’ve done for almost 30 years, and the same we will do for decades more to come.”