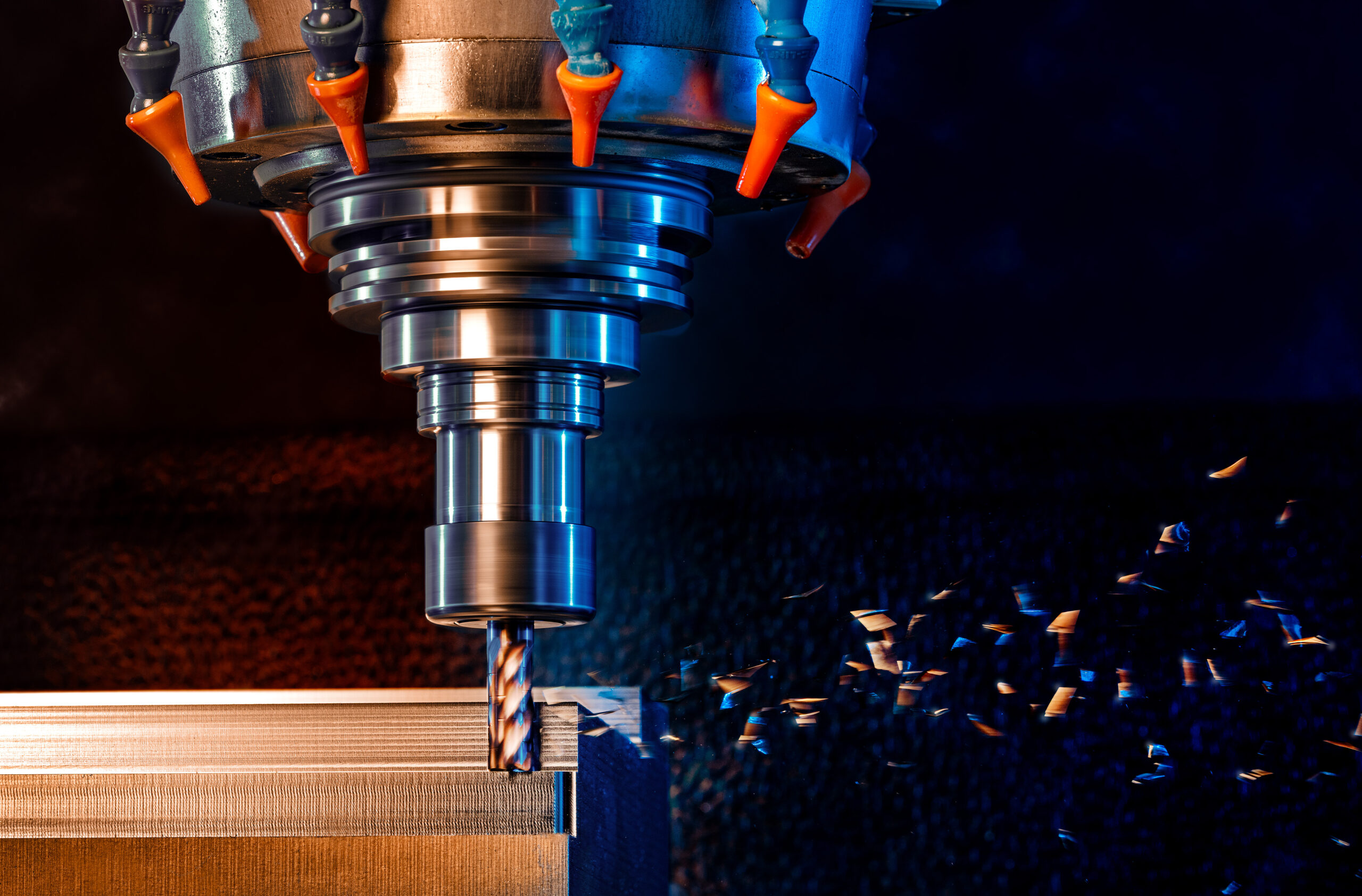

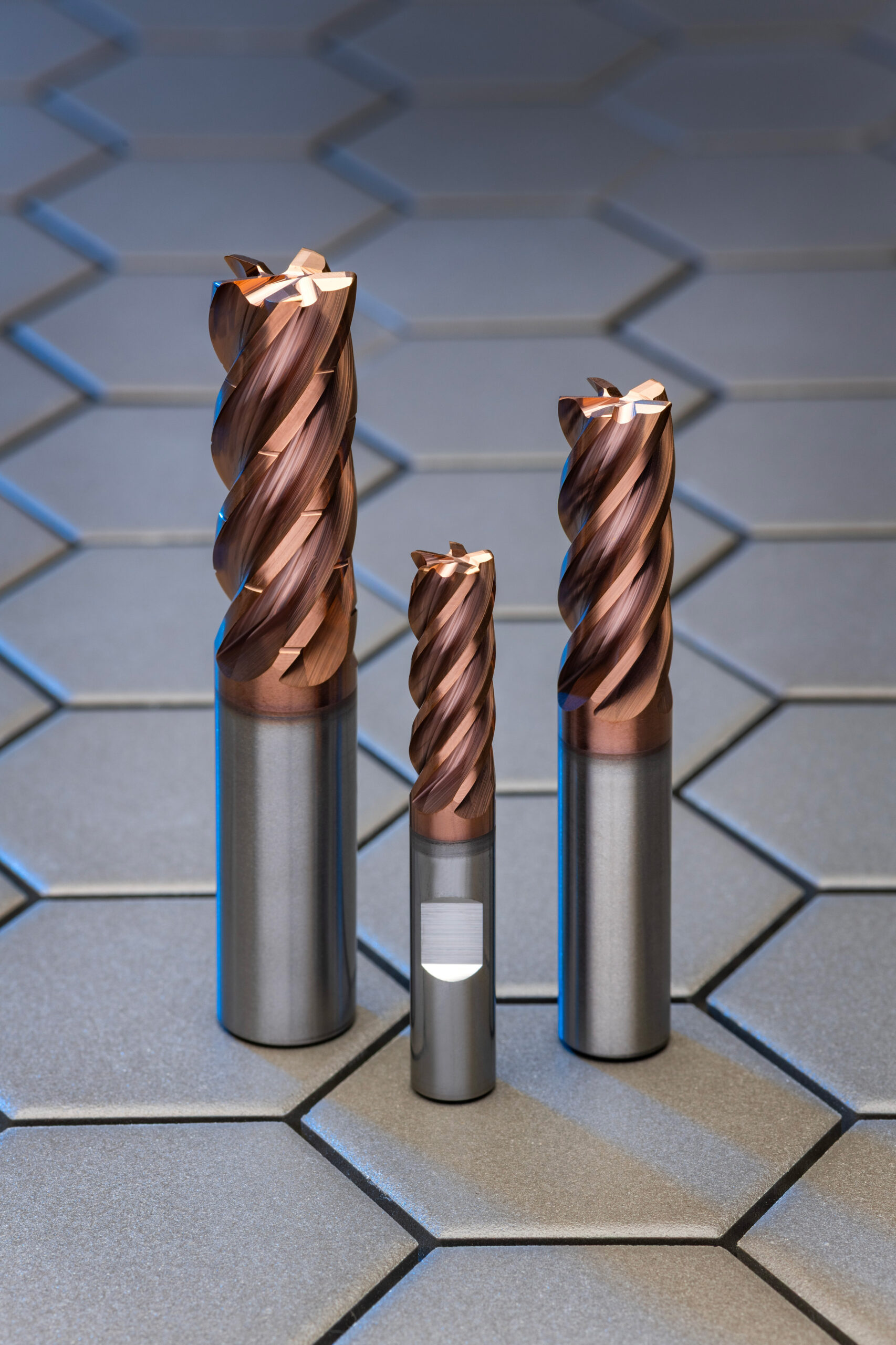

Perrysburg, Ohio, USA – September 1, 2025 – IMCO Carbide Tool is launching the next iteration of POW•R•FEED cutting tools: new POW•R•FEED M935 5-flute end mills created with a revolutionary new grinding process for amazingly higher metal removal rates and the freeest cutting action in mild steels, stainless steels and titanium.

Perrysburg, Ohio, USA – September 1, 2025 – IMCO Carbide Tool is launching the next iteration of POW•R•FEED cutting tools: new POW•R•FEED M935 5-flute end mills created with a revolutionary new grinding process for amazingly higher metal removal rates and the freeest cutting action in mild steels, stainless steels and titanium.

“Our primary goal is to help our customers cut through any barriers to higher productivity,” said Matt Osburn, Vice President, Technical Director for IMCO. “This new POW•R•FEED M935 line puts a lot of new possibilities on the table, especially for shops using conventional machining.”

“Our mission was to develop faster, more productive end mills capable of higher speeds and extremely aggressive tool paths in the materials machine shops use most,” Osburn said. “These M935 end mills prevent clogs – so that downtime goes away – and cut faster to maximize your output, no matter what kind of machining centers you use.”

Multi-Parabolic Grinding

IMCO employs a revolutionary process called multi-parabolic grinding

(MPG) to produce unique end face, flute and core geometries that make extremely aggressive tool paths possible – even with complex movements.

face, flute and core geometries that make extremely aggressive tool paths possible – even with complex movements.

“Those special geometries work together to eliminate chip pollution and crank the MRR higher at speeds you never thought possible,” Technical Support Manager Steve Avers explained. “This free cutting action means you can run to the machine’s upper capacity. Of course, M935 end millsalso get an exclusive high-lubricity AlTiSiN coating to keep those chips flying and keep the tools running cooler. And it’s especially great at plunging and slotting.

NEW POW•R•FEED M935 END MILLS – 2

“You get faster feed rates, shorter cycle times, maximized output and greater profits, every shift, every day.”

“You get faster feed rates, shorter cycle times, maximized output and greater profits, every shift, every day.”

POW•R•FEED M935 end mills’ unique flute and core designs also open the door for extremely aggressive tool paths, stepovers and depths. The core is super-tuff carbide with a business end that offers fine cutting edges with amazing strength plus a wiper flat end for smooth floor finishes. All edges are prepped for long, long life.

POW•R•FEED M935 end mills are an extension of IMCO’s POW•R•FEED M9 workhorse end mills. Already very affordable altern

atives to competitors’ high-performance tools for machining these metals, IMCO M935 end mills save users at every turn. Overall, for all tools in the POW•R•FEED line, the price-to-performance ratio is exceptional.

“This is a highly competitive industry,” Osburn said. “It’s our privilege to give our customers every advantage they need for higher productivity and profitability.”

Learn more about POW-R-FEED M935 end mills. Call 1-800-765-4626 (USA) or 419-661-6313 (international) or visit www.imcousa.com.

Learn more about POW-R-FEED M935 end mills. Call 1-800-765-4626 (USA) or 419-661-6313 (international) or visit www.imcousa.com.

About IMCO Carbide Tool Inc.

Since 1977, IMCO Carbide Tool Inc. has focused on one goal: To provide manufacturers in a variety of industries with technologically advanced tools that will help them achieve new levels of profitability, customer satisfaction and a competitive advantage. By revolutionizing the way their tools are designed, produced, tested and used, IMCO strives to meet the ever-changing needs of a technologically diverse customer base. Now, as part of The IMC Group, IMCO will continue to focus investments on issues that matter most to users – product quality, performance and service. For more information, call 1-800-765-4626 or visit imcousa.com.

About the IMC Group

Comprised of 13 companies, with over 130 subsidiaries in 60 countries, the IMC Group has a portfolio of companies that produce a comprehensive line of high-precision carbide metalworking tools. A wholly owned subsidiary of Berkshire Hathaway, the IMC Group is headquartered in Tefen, Israel, where it was founded in 1952. Since then, it has grown to become the second-largest company for metal-cutting products in the world. Find out more at imc-companies.com .