86

www.CNC-West.comCNC WEST December 2016/January 2017

New Products

protection, users have access only to

those portions of the software that their

level of qualification allows.

The modular design principle

means that the measuring machine can

be expanded to meet future require-

ments at any time. It is even possible

to retrofit an image processing sensor

and other optical sensors.

CoroPlus™ Brings Con-

nectivity to Manufacturing

Plants

—Sandvik Coromant

Cutting tool and tooling systems

specialist Sandvik Coromant has

unveiled its CoroPlus™ suite of

Industrial Internet of Things (IIOT)

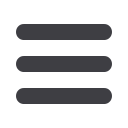

5-Axis Gantry Mill

• 5/6 Axis - Up to 6 Meters Travel

• Travelling Column

• General Options

- Automatic Head Change

- Automatic Tool Change

- Friction Stir Welding

- Milling

• Working Area:

- Travel range

X:

78,7 up to 236 in

Y: 59 up to 118,1 in

Z: 39,4 up to 47,2 in

• Milling Head:

- Swivel range A: +/- 110°

- Swivel range C: +/- 360°

- Max. Torque: 738 lb

• Tool Magazine:

- 48 / 64 Places

818.429.5114

CYPORT

Dynamic • Accurate • Economic • Universal

MADE IN GERMANY

solutions aimed at helping manufac-

turers prepare for Industry 4.0. The

concept is designed specifically to

improve the control of productiv-

ity and costs through a combination

of connected machining and access

to manufacturing data and expert

knowledge.

CoroPlus is the umbrella name for

a new platform of connected tools and

software; essentially comprising tech-

nologies that can send and/or receive

data. The concept makes it possible

to reduce data waste and improve

manufacturing processes, from pre- to

post-machining, through the use of

connected technology and machining

knowledge from Sandvik Coromant.

Sandvik reports the principal ben-

efit for production managers is that

CoroPlus makes it possible to opti-

mize manufacturing through better

understanding and insight into what’s

happening in the workshops and ma-

chining environment, on either a micro

or macro level.

From a CAM programmer’s per-

spective, connection with accurate tool

and application data means that recom-

mendations can be adapted to specific

tasks. There are also advantages for

operators as machining processes can

be monitored remotely. Furthermore,

specific sensor-equipped tools can be

controlled to ensure that breakages are

avoided and performance is secured

with data intelligence collected live

throughout the machining process.

The offer currently comprises

dashboard solutions, software solu-

tions in CoroPlus Tool Guide and

Adveon™ Tool Library, as well as

Silent Tools™+ and CoroBore®+

cutting tools, and Promos 3+ machine

monitoring IoTsystem.