22

www.CNC-West.comCNC WEST December 2016/January 2017

G

ear Manufacturing, Inc. (GMI), Anaheim, CA, was

founded in 1989 with a mission to manufacture

high-quality custom gears and gear-related com-

ponents and assemblies. Housed in 27,500-square-foot facili-

ties, the company is equipped with the latest CNC machining

centers supported by extensive engineering capabilities and

leading-edge software. The company makes almost every type

of precision gear configuration imaginable, which it produces

in materials ranging from tool steel and titanium to cast iron,

copper, all types of alloys and engineered plastics – virtually

any material that can be used to cut a gear.

Approximately two-thirds of GMI’s output is dedicated to

the aerospace and defense industries and includes customers

such as Northrop Grumman, Lockheed Martin and Boeing,

as well as the Bell Helicopter and Sikorsky Aircraft. It will

come as no surprise that GMI products comply with stan-

dards promulgated by the American Gear Manufacturer’s As-

sociation (AGMA), Deutsches Institute Fur Normung (DIN),

National Aerospace Society (NAS), the Society of Automo-

tive Engineers (SAE), and the American Society of Mechani-

cal Engineers (ASME). In addition, GMI’s processes comply

with AS9100 – the aerospace version of the ISO9000 quality

management system – recognized internationally by both the

SAE and the European Association of Aerospace Industries.

Specifically, GMI complies with Rev. C of AS9100 released in

January 2009, and which adds an emphasis on risk mitigation.

Not unexpectedly, GMI’s adoption of AS9100 Rev. C has

had a major impact on the company’s approach to manufac-

turing management.

RISK MANAGEMENT AND MITIGATION

Risk management and mitigation is the identification, as-

sessment and prioritization of risks. As defined by AS9100

Rev. C, risk is

the effect of uncertainty, whether positive or neg-

ative on achievement of objectives

. Risks causing uncertainty

can derive from project failures (at any phase in design, de-

velopment, production or sustaining life-cycles), legal liabili-

ties, financial markets and credit risk, as well as accidents and

natural causes. Strategies to mitigate risk typically include re-

ducing the probability of the risk, reducing the negative effect

should the risk occur, transferring the risk to another party,

avoiding the risk, or even accepting some or all of the potential

or actual consequences of a particular risk.

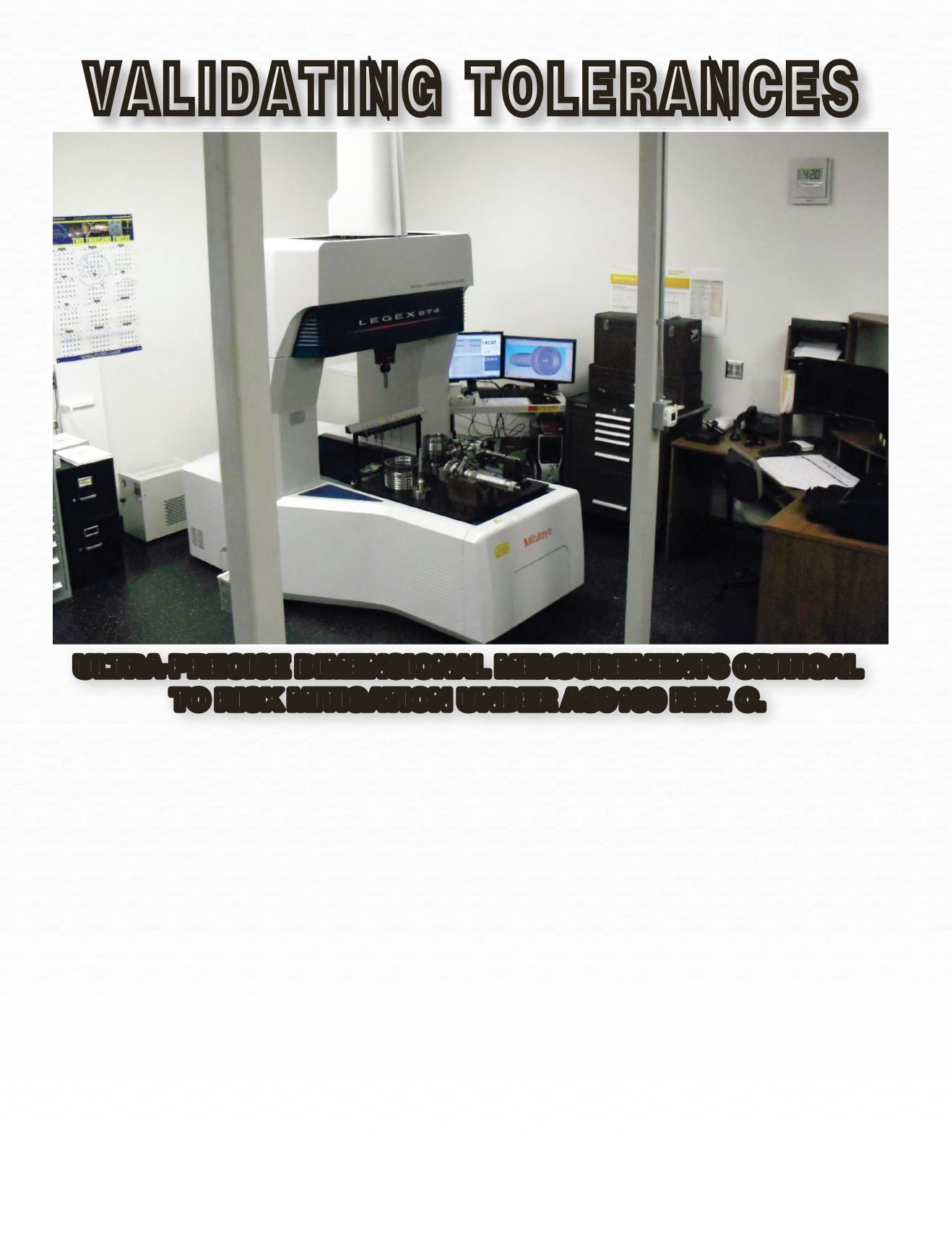

VALIDATING TOLERANCES

ULTRA-PRECISE DIMENSIONALMEASUREMENTS CRITICAL

TORISKMITIGATIONUNDER AS9100 REV. C.

Mitutoyo Legex 574 CNC CMM as installed in the

Gear Manufacturing, Inc. metrology laboratory.