80

www.CNC-West.comCNC WEST October/November 2016

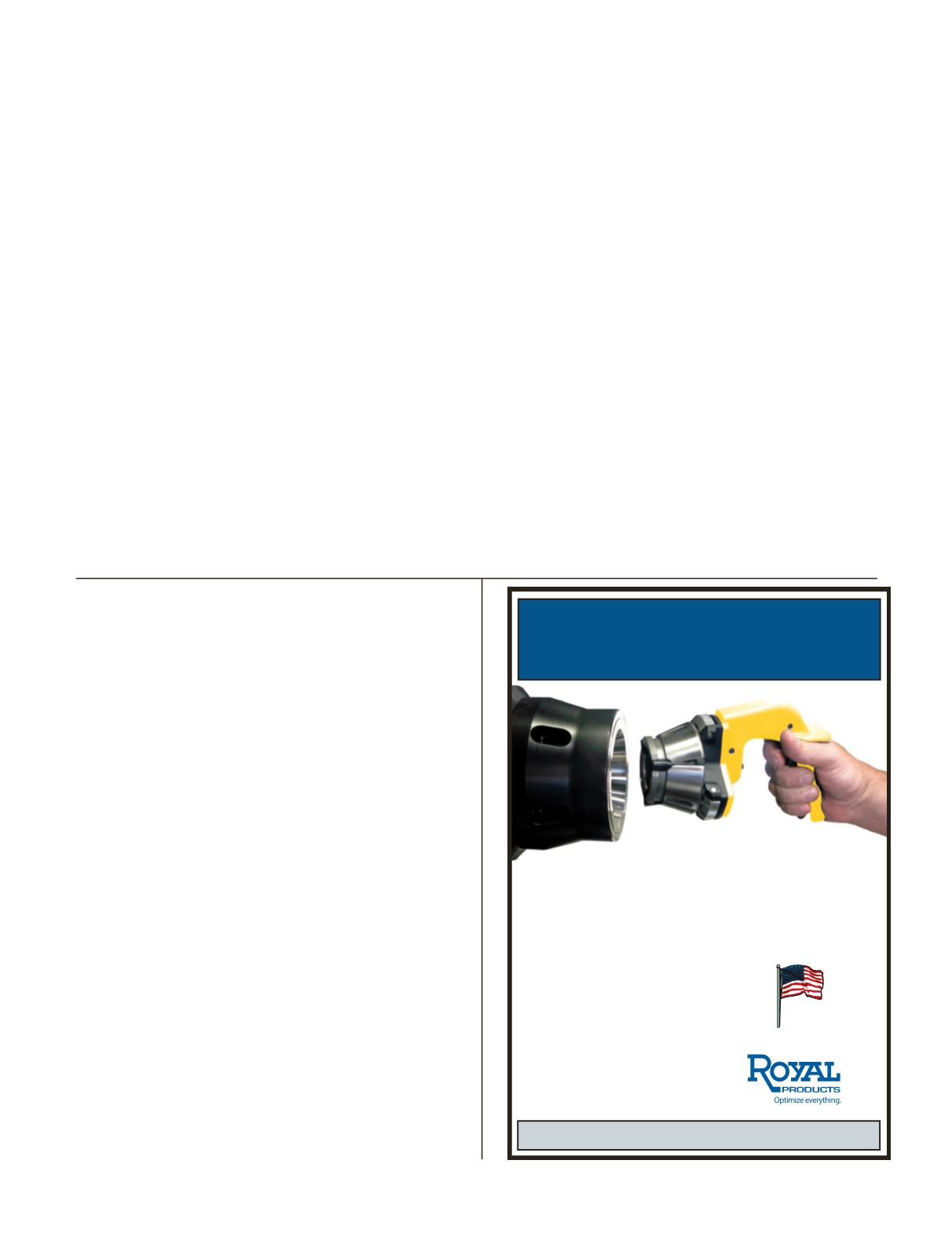

10-Second

Collet Changes

Call: 1-800-645-4174 •

www.colletchucks.comThe Royal Quick-Grip™ is the smart workholding solution

designed to optimize all of your CNC Turning applications:

• Amazing 10-second collet changes

• Extremely Accurate – 0.0002" TIR

• Most compact length & diameter

• Widest gripping range – 0.062"

• Full 360° workpiece contact

• Perfect for bar feeding applications

• Fast and easy Bolt & Go™ installation

• Risk-free performance guarantee

Replace Your Outdated Chucks

Today with Royal Quick-Grip

™

Proudly

Made

inU.S.A.

NOT YOUR FATHER’S DRILLS

www.genswiss.com(413)562-4800

Available from

...introducing the INOX 370 Series for Stainless

Super-Developed and Refined

Geometry for Advanced Performance

in Stainless Steels

Dramatically Lowers Cost Over

Conventional Drills in Stainless

Diameter Tolerance -.002mm / -.004mm

Micro Sizes - .5mm thru 3mm Diameter

Integrated Chip Breaker Reduces

Entangling Stringy Chips

Next Generation of Preci-

sion Micromachining

—OMAX

The latest model of the MicroMAX

includes accuracy enhancing upgrades

and expanded accessory compatibility.

“Since its introduction, the Micro-

MAX has offered industry leading part

precision,” says Michael Ruppenthal,

vice president of NorthAmerican sales

for OMAX. “Some of the world’s

leading high tech companies and in-

stitutions have chosen the MicroMAX

for work ranging from prototyping to

production because of its accuracy

and ease of use. We’ve engineered our

next generation MicroMAX to deliver

more capabilities and benefits to our

customers”.

With this release, the OMAX Tilt-

A-Jet cutting head comes standard

for even greater precision and virtu-

ally zero taper when working with

most materials. Contributing to the

ultra-high precision capability of the

MicroMAX is OMAX’s proprietary

linear traction drive system that utilizes

optical encoders to provide a position-

ing accuracy of less than five microns.

Protective bellows seal off all precision

components inside the MicroMAX and

the machine’s rigid construction mini-

mizes vibration.Acatcher tank cooling

package is now an option available to

keep the water at a steady 72°F.

The MicroMAX is now compatible

with the OMAX Precision Optical

Locator (POL) as an add-on accessory.

The POL can locate existing points,

edges or holes in a pre-machined part

for secondary machining operations

or reverse engineering of a part where

this is permissible. The rotary axis is

another optional accessory compatible

with the MicroMAX for full 6-axis

machining.

A steel, epoxy-coated enclosure

with sliding doors covers the Micro-

MAX system for quiet, clean machin-

ing. A mobile work station with easy-

to-use controller software provides

the operator with convenient set-up

and monitoring capability. This latest

model of the MicroMAX is compat-

ible with the OMAX Variable Speed

Solids Removal System (VS-SRS)

to efficiently remove garnet from the

waterjet catcher tank.

New Products